Over the past few years, resin 3D printing has emerged as a powerful technology that delivers exceptional detail and quality in your prints. If you’re eager to look into the exciting world of resin printing, you’ll need to understand the important equipment, safety precautions, and techniques that set it apart from traditional FDM printing. This guide will help you navigate the basics, ensuring you make informed decisions as you begin on your resin printing journey.

What is Resin Printing?

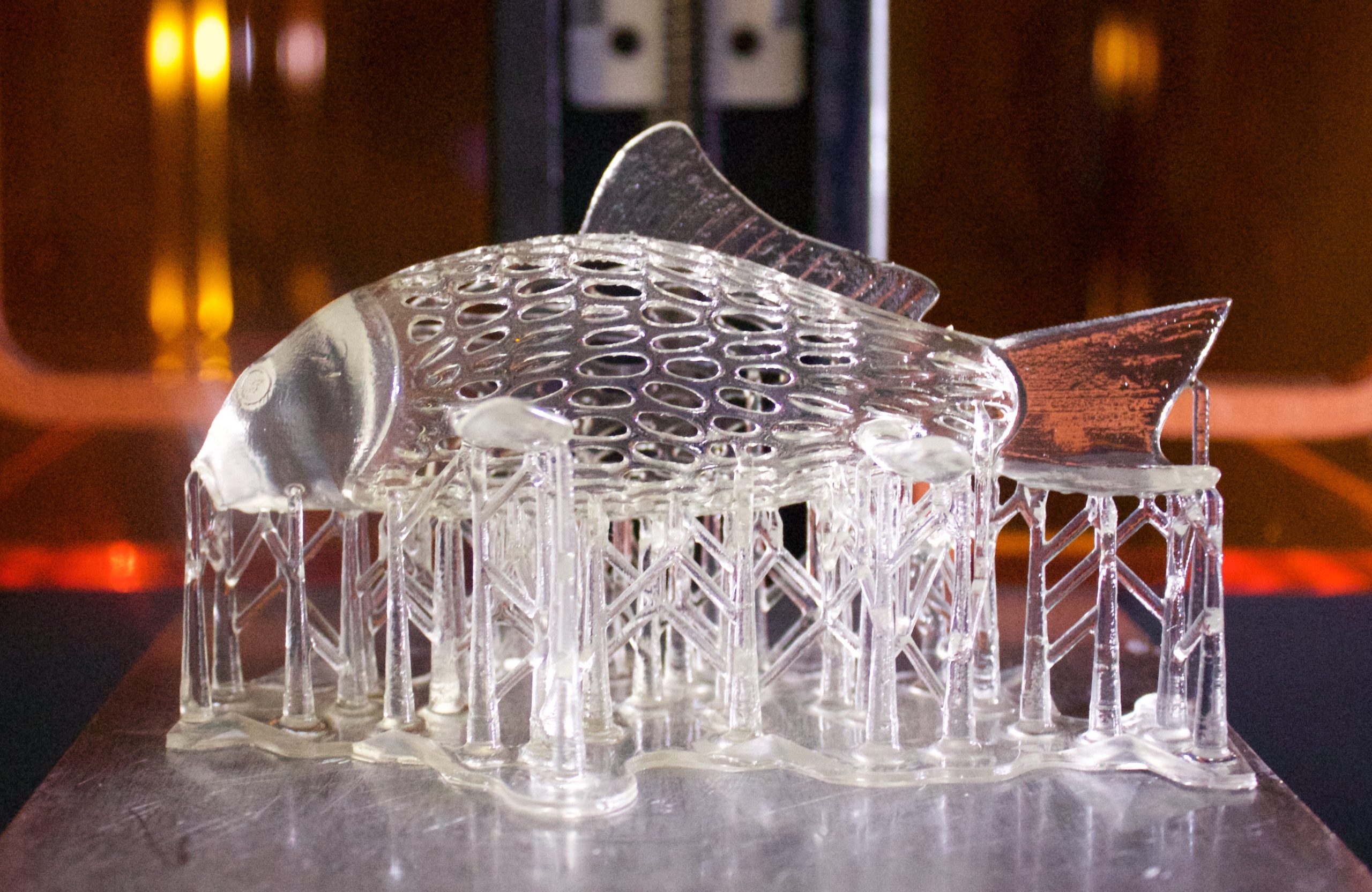

The process of resin printing involves using ultraviolet light to cure photosensitive resin layer by layer, resulting in highly detailed 3D prints. Unlike traditional FDM printing, where filament is extruded through a nozzle, resin printers can produce layers as thin as 0.05 mm, offering superior print quality. This technology is particularly beneficial for printing intricate designs, models, and miniatures that require precision and finesse.

Understanding the Technology

Clearly, resin printing operates on a unique principle where a UV light source selectively hardens resin in a vat. By blocking UV light with a screen, the printer can cure entire layers simultaneously. This method not only enhances print speed but also enables the creation of highly detailed models, making it an appealing choice for hobbyists and professionals alike.

Benefits and Drawbacks

Any 3D printing method comes with its own set of benefits and drawbacks. While resin printing delivers exceptional detail and faster print speeds for intricate models, it necessitates extensive post-processing, including cleaning with chemicals and UV curing, which can be labor-intensive and might deter beginners. Moreover, the handling of uncured resin presents safety concerns, requiring protective equipment and a well-ventilated workspace.

Benefits include the ability to achieve superior print quality, as resin printers can produce very fine details that surpass FDM capabilities. However, the downsides encompass a more complex workflow, involving additional steps like cleaning and curing, which can be cumbersome. You should weigh these factors against your specific printing needs to determine if resin printing is the right choice for you.

Essential Safety Precautions

Assuming you are new to resin printing, it’s vital to prioritize safety to ensure a smooth and enjoyable experience. Resin printing involves handling substances that can be harmful if not treated with care. Always take the necessary precautions to protect yourself and your workspace, as proper safety measures can prevent accidents and health issues while working with resin.

Handling Uncured Resin Safely

On handling uncured resin, it’s vital to wear protective gloves and avoid direct skin contact. Uncured resin can cause burns or irritations, so if you accidentally touch it, wash the area immediately with soap and water. Treat resin bottles with care to prevent spills, fostering a safe working environment.

Importance of Ventilation

Uncured resin emits harmful fumes, making proper ventilation critical during the printing process. Ensure your workspace is well-ventilated, preferably using a separate room to minimize exposure to these vapors. Utilizing a face mask while working can greatly reduce the inhalation of any lingering fumes, improving your overall safety and comfort during resin printing.

Importance of proper ventilation in resin printing cannot be overstated. Fumes from uncured resin and cleaning chemicals can pose health risks, so creating a well-ventilated workspace protects you from inhaling these harmful substances. If you can’t dedicate a separate room for printing, consider an air filtration system or wearing a respirator to safeguard your health while exploring the creative possibilities of resin printing.

Choosing the Right Resin Printer

Some factors to consider when choosing your first resin printer include the types of models you plan to print and the available space in your workshop. Whether you’re a hobbyist or looking to start a small business, there’s a suitable printer for you. For a comprehensive overview, check out this 3D Resin Printing For Beginners – A Step by Step Guide.

Small Format Printers

You will find that small format resin printers are ideal for printing miniatures or jewelry. These printers are compact, affordable, and perfectly suited for hobbyists or those new to resin printing, offering high-resolution prints without occupying much space.

Large Format Printers

Printers designed for large format resin outputs are perfect for scaling up your production or experimenting with larger models that can’t fit on smaller machines. These printers typically provide a larger build area, enabling you to print multiple small models simultaneously or create large, intricate designs in a single piece.

Printers such as the Anycubic Photon Mono X and ELEGOO Saturn offer excellent build volumes without compromising on quality. They are often favored by enthusiasts and small business owners who require the ability to tackle more ambitious projects while also maximizing efficiency by producing multiple items at once.

Key Post Processing Techniques

Your post-processing techniques will greatly influence the quality of your resin prints and are necessary for achieving the best results. After printing, you need to wash and cure your models to ensure they are clean and fully hardened. For a comprehensive understanding, check out Resin 3D Printing for Beginners: Your Step-by-Step Guide ….

Washing Techniques

Some effective washing techniques involve using isopropyl alcohol or dedicated wash stations that simplify the cleanup process. These methods help remove uncured resin from your prints, which is important to avoid skin irritation and ensure proper curing.

Curing Methods

The curing process is vital for achieving the final hardness and durability of your prints. Proper curing involves exposing your models to UV light, which hardens the remaining resin and enhances the print’s structural integrity. Using specialized curing stations can streamline this process.

Understanding the curing process is necessary for maximizing the quality of your prints. Layer by layer, resin models need adequate UV exposure to eliminate any uncured resin. Different curing methods include using UV lamps, sunlight, or dedicated curing stations made for 3D prints. These stations not only provide a controlled environment but often include features that allow for efficient post-processing, making them a worthy investment for any resin printer owner.

Required Tools and Consumables

Once again, before venturing into resin printing, ensure you have the proper tools and consumables at hand. Aside from the resin printer itself, you will need photosensitive resin, gloves, and all necessary safety gear. This preparation helps streamline your printing process while prioritizing your safety and the quality of your prints.

Selecting the Right Resin

Required for achieving optimal print results is the selection of the right resin. Various types of resin exist, ranging from standard options like Anycubic Basic resin for general use to specialty resins with unique properties, such as flexible or high-detail variants. Assess your specific printing needs before deciding on a resin type.

Essential Post Processing Equipment

Right after printing, you’ll need vital post-processing equipment to finalize your models. This includes wash and cure stations, which efficiently clean and cure your prints in one unit. Without proper post-processing, the quality and durability of your prints can be compromised, making this equipment indispensable to your workflow.

Equipment such as the Anycubic Wash and Cure or the ELEGOO Mercury Plus simplifies this messy process, allowing you to focus more on your projects. These all-in-one solutions save space and time, ensuring that your printed models are thoroughly cleaned and cured for best results. Investing in a quality wash and cure station ensures your prints are not only visually appealing but also durable for practical use.

Tips for Successful Prints

Despite the challenges of resin printing, you can achieve impressive results by following these vital tips:

- Use high-quality resin to enhance detail and reduce errors.

- Ensure proper ventilation in your workspace to minimize exposure to fumes.

- Always wear protective gear when handling uncured resin.

- Adjust your print settings according to the model’s complexity and size.

Assume that by applying these tips, your printing experience will become more enjoyable and productive.

Optimizing Print Settings

Little adjustments to your print settings can significantly improve the quality of your prints. Focus on layer height, exposure time, and lift speed to find the ideal balance for your specific printer and resin type. Testing different settings with small print runs will guide you in identifying optimal conditions.

Maintaining Your Printer

Print maintenance is vital to keep your resin printer functioning optimally. Regularly check for any resin leaks, clean the build plate and vat, and monitor the condition of the LCD screen to ensure a smooth printing process.

To maintain your printer, establish a routine for cleaning the build plate and vat after each print. Ensure that any leftover resin is removed to avoid contamination in future prints. Additionally, periodically inspect internal components for wear or buildup, and replace parts as needed to prolong the life of your printer.

Conclusion

Conclusively, starting your journey in resin printing involves understanding the unique aspects of this technology, prioritizing safety, and selecting the right printer for your needs. Invest in quality post-processing tools to streamline cleanup and curing, and choose the appropriate resin for the projects you plan to undertake. By following this guide, you will be well-equipped to create high-quality prints and enjoy the advantages that resin 3D printing offers.

Leave a Reply