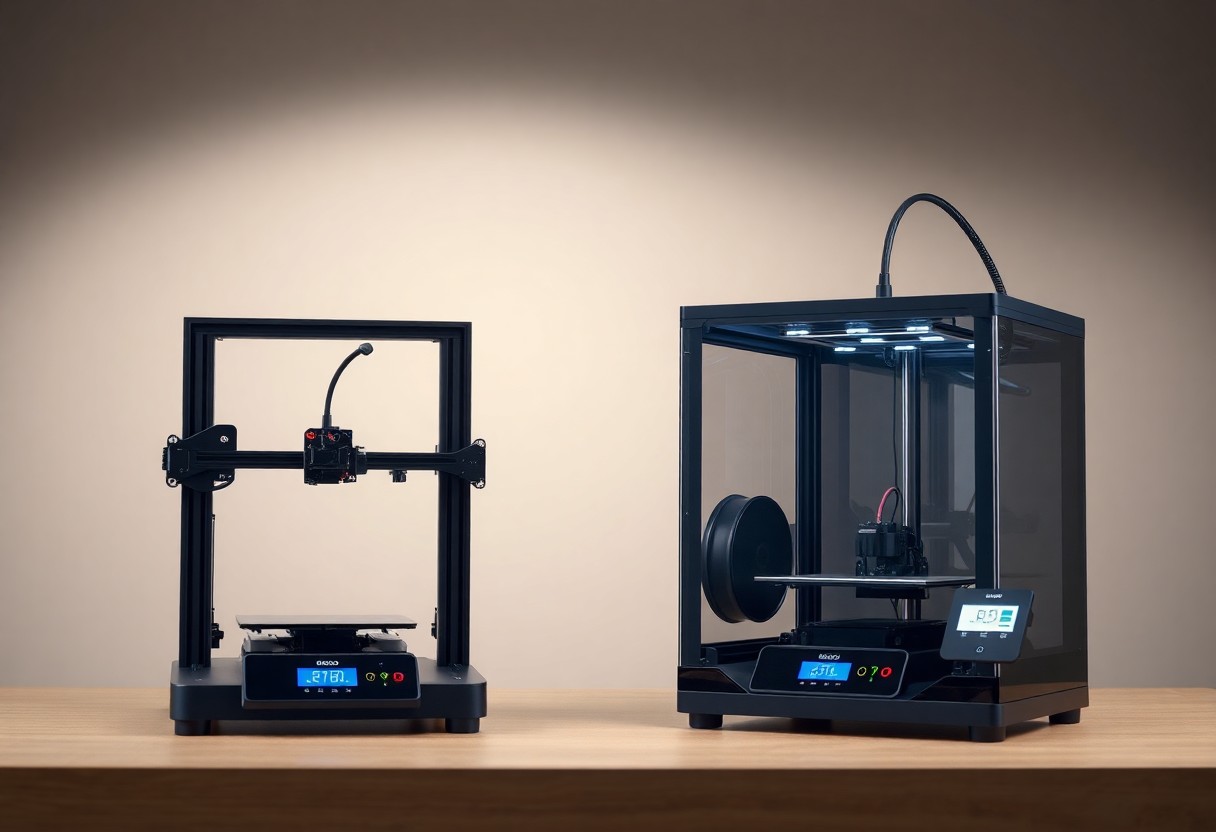

With the ever-evolving landscape of 3D printing technology, you might be wondering which high-end enclosed CoreXY printer deserves your investment. The newly launched Elegoo Centauri Carbon enters the arena as a formidable challenger to the established Bambu X1C, bringing innovative features that could reshape your printing experience. In this detailed comparison, you’ll discover how these two powerhouses stack up against each other in terms of build quality, print speed, and user-friendly features, helping you make an informed decision for your next 3D printing upgrade.

Background and Context

Any journey into the world of 3D printing technology reveals a fascinating evolution from basic prototyping tools to sophisticated manufacturing solutions. As you explore the current landscape of 3D printing, you’ll find that modern printers like the Bambu X1 Carbon represent the culmination of years of technological advancement and innovation in additive manufacturing.

Evolution of 3D Printing

One of the most significant transformations you’ve witnessed in 3D printing technology is the shift from complex, manually-operated machines to smart, automated systems. When you look back at the early days of consumer 3D printing, you’ll notice that users needed extensive technical knowledge and patience to achieve even basic prints, while today’s machines offer plug-and-play functionality that makes the technology accessible to everyone.

Modern 3D Printing Features

Printing technology has evolved to include features that make your experience more reliable and efficient. You’ll find that modern printers come equipped with auto-bed leveling, advanced cooling systems, and sophisticated motion control systems that help you achieve consistent, high-quality results with minimal effort.

Any modern 3D printer you encounter today will likely include features like network connectivity, remote monitoring capabilities, and advanced material handling systems. These innovations allow you to manage your prints more effectively, whether you’re working from home or monitoring your printer from a distance through your smartphone or computer.

Product Features

Some of the standout features you’ll find in the Centauri Carbon include an advanced auto-bed leveling system, integrated filament runout detection, and a user-friendly touch interface. You’ll appreciate the built-in WiFi connectivity that allows for remote print monitoring and control through Elegoo’s dedicated app. The printer also comes equipped with a dual-gear direct drive extruder system, ensuring precise filament control and compatibility with a wide range of materials.

Build Quality and Materials

Assuming you’re looking for a printer that’s built to last, you’ll be pleased with the Centauri Carbon’s construction. Your investment is protected by its die-cast aluminum alloy frame, which provides exceptional stability during high-speed printing operations. The tempered glass panels not only offer clear visibility of your prints but also help maintain consistent internal temperatures for optimal printing conditions.

Technical Specifications

One of the most impressive aspects you’ll discover about the Centauri Carbon is its generous build volume of 250x250x250mm, allowing you to tackle larger printing projects with ease. The printer features a maximum print speed of 500mm/s with acceleration up to 20,000mm/s², putting it in the high-performance category of consumer 3D printers.

Any concerns about print quality at high speeds are addressed by the printer’s advanced motion system, which includes linear rails on all axes and a sophisticated 32-bit controller board. You’ll find the printer’s ability to maintain temperatures up to 320°C in the hot end and 100°C on the build plate gives you the flexibility to work with a wide range of materials, from basic PLA to more demanding engineering plastics.

Design Architecture

After examining the X1 Carbon’s construction, you’ll notice its sophisticated design architecture that combines durability with elegance. The chassis features a precision-engineered framework that utilizes aerospace-grade materials, giving you confidence in its structural integrity while maintaining a remarkably slim profile.

CoreXY Technology Explanation

To understand the X1 Carbon’s movement system, you should know that it employs a unique belt arrangement where two belts work in parallel to control the print head’s motion. When you initiate a print, these belts coordinate their movements through a series of pulleys, allowing your print head to move precisely in both X and Y directions simultaneously.

Advantages Over Traditional Designs

On your first print with the X1 Carbon, you’ll immediately notice the improved stability compared to traditional printers. Your prints benefit from reduced vibration and enhanced accuracy since the print head is the only moving component in the X and Y axes, while your build plate only moves vertically.

Over time, you’ll appreciate how this design brings you multiple benefits: your maintenance needs are reduced due to fewer moving parts, your print speeds can be significantly higher without sacrificing quality, and your printer’s footprint remains compact despite offering a generous build volume. The enclosed design also helps you maintain consistent temperatures, especially when printing with materials that require specific environmental conditions.

Special Features and Accessories

To make your 3D printing experience more comprehensive, the Elegoo Centauri Carbon comes equipped with an array of special features that set it apart from conventional 3D printers. You’ll find everything from advanced monitoring capabilities to innovative plate systems, all designed to enhance your printing workflow and results.

Camera and Time-Lapse Capabilities

Any time you want to check on your print progress, you can do so remotely through the integrated camera system. You’ll appreciate the ability to monitor your prints in real-time through the Elegoo Slicer software, giving you peace of mind during those longer printing sessions. The built-in lighting system ensures your prints are clearly visible at all times.

Double-Sided Magnetic Plate System

Now you can enjoy enhanced versatility with the innovative double-sided magnetic build plate. You’ll find a smooth surface on one side, perfectly suited for your PLA prints, while the other side features a textured PEI coating ideal for materials like PETG, TPU, ABS, and carbon fiber filaments.

System flexibility is at your fingertips with this dual-surface approach. You can easily switch between surfaces by simply removing the magnetic plate, flipping it over, and reattaching it – no tools required. The strong magnetic hold ensures your build plate stays firmly in place during printing, while still allowing for easy removal when you need to change sides or remove completed prints.

Leave a Reply